1. Casting brake surface blanks+:

In the research and development of brake disc manufacturing, brake performance is the top priority, its material selection, wear resistance coefficient and thermal expansion coefficient directly determine the quality and safety of products. We use high carbon gray cast iron as the core material of brake body, this material selection has significant advantages

In terms of material characteristics, high carbon gray cast iron is based on high carbon content, and the graphite in the interior is evenly distributed in the matrix structure. This unique microstructure endows the material with excellent shock absorption and noise reduction performance, which can effectively buffer the high-frequency vibration generated during braking, reduce harsh noise, and improve driving and riding comfort.

In terms of wear resistance, high-carbon gray cast iron, thanks to its unique composition and microstructure, exhibits outstanding wear resistance. Professional tests have confirmed that its wear resistance coefficient is among the industry's best, capable of withstanding tens of thousands of high-intensity braking cycles. Even under harsh conditions such as frequent braking and heavy loads, it maintains stable friction performance, significantly extending the service life of the brake disc.

In terms of thermal stability, the low coefficient of thermal expansion of high-carbon gray cast iron is a significant core advantage. In extreme conditions where continuous braking causes the brake surface temperature to spike (up to over 600℃), the material's dimensional change rate remains minimal, maintaining the precision of the disc geometry. This ensures the stability and reliability of the braking system, thereby preventing brake failure risks caused by thermal deformation at their root.

2. Make a joint:

In the design of the brake disc's key components, we have meticulously crafted the joint area. The joint is made from high-strength drawn steel, which boasts excellent tensile strength and fatigue resistance. This material effectively withholds stress impacts in complex road conditions during vehicle operation, ensuring the stability and safety of the brake disc.

In terms of manufacturing process, we use professional grade stamping die and one-time stamping forming technology. This process not only ensures the integrity and consistency of the joint structure, but also greatly improves the dimensional accuracy and surface quality of the part

The joint thickness is precisely controlled at 2.5mm, which aligns perfectly with the original factory specifications. This ensures that during later installation and use, there is no need to replace or extend bolts, allowing for direct compatibility with the vehicle's existing mounting system. This not only saves time and costs but also avoids potential compatibility issues caused by mismatched specifications, providing users with a convenient and reliable installation experience.

3. The head is combined with the brake body:

In the design of the brake disc core structure, we innovatively adopted a mechanical locking fitting technology (patented): a high-strength steel head is securely embedded into a high-carbon cast iron blank through precise manufacturing processes. This technique ingeniously utilizes the different thermal expansion coefficients of the two materials —— During high-speed braking, the friction on the brake surface causes the high-carbon cast iron blank to expand, while the steel head expands less. The resulting thermal stress acts like a 'tightening spring,' further tightening the steel head and creating a dynamic locking effect that becomes tighter with use.

After rigorous fatigue tests, even after tens of thousands of high-temperature braking cycles, this self-reinforcing locking structure can still maintain zero clearance fit, eliminate the hidden dangers such as abnormal sound and vibration caused by loose parts from the root, provide consistent stable performance for the vehicle braking system, and protect every safe travel with hard core technology.

4. Compare with the original factory:

Our brake disc manufacturing process is markedly different from that of the original Mercedes-Benz, offering significant advantages. The original Mercedes-Benz uses a riveting technique, which, despite being a traditional method, has been found to have several drawbacks in market feedback: over time, due to thermal expansion and other factors, the riveted joints can become loose under vibration, leading to gaps between the joint and the disc body, which can cause abnormal braking sounds and vibrations. Additionally, the stress concentration at the riveted joints can lead to localized fatigue damage, shortening the brake disc's lifespan and affecting the stability of the braking system.

By innovatively applying mechanical locking fitting technology, we break through the limitations of traditional processes and achieve long-term stable connection with material characteristics and precision structural design. In contrast, in terms of durability, reliability and braking experience, it shows technical advantages far beyond that of traditional riveting process.

5. Rough processing:

In the manufacturing process of brake discs, we use CNC numerical control machining technology to establish a high-precision production foundation. During the initial rough processing stage, CNC machine tools perform high-speed milling and turning operations to quickly remove excess material from the surface of the blank, precisely control the contour dimensions, and reserve a scientifically reasonable machining allowance for subsequent processing. This process not only

It can effectively improve the utilization rate of materials, and ensure that the initial size, precision and processing benchmark of each product are unified through standardized CNC program, laying a solid foundation for the second step of precision machining, and ensuring the high precision and consistency of finished products from the source.

6. Finishing + brake grinding:

After rough machining, we enter the critical finishing process. We use a professional horizontal brake grinding lathe to ensure brake quality through a precise two-step process:

First, the double-tool integral turning process is employed, utilizing high-precision dual tools to perform synchronized operations on both the front and rear brake surfaces of the brake disc. This process, controlled by a CNC system with micron-level precision, ensures that the flatness and parallelism errors of both surfaces are kept to an extremely small range. It also guarantees that the key parameters of the front and rear brake surfaces are highly consistent, laying the foundation for uniform force distribution and stable friction during braking.

Subsequently, the brake surface is finely processed using a special grinding tool through the lathe's brake surface rubbing process. This step effectively eliminates the machining marks, reduces surface roughness, and optimizes the micro-geometric structure of the brake surface, thereby stabilizing the friction coefficient and further enhancing the braking performance and service life of the brake disc.

7. Dynamic balance test:

After the precision machining is completed, the brake disc will undergo dynamic balance testing, a critical quality control step. We use high-precision dynamic balance testing equipment to simulate the rotational conditions of the brake disc during high-speed vehicle operation, detecting the uniformity of mass distribution on the brake surface and the entire disc body with micrometer-level accuracy. The equipment can accurately identify imbalances caused by factors such as material density differences and machining errors. Once an imbalance is detected, the equipment automatically initiates heavy-duty correction to ensure the brake disc operates with zero vibration and zero eccentricity. This prevents issues like braking noise and steering wheel vibrations caused by dynamic imbalance, providing users with a smooth and safe braking experience.

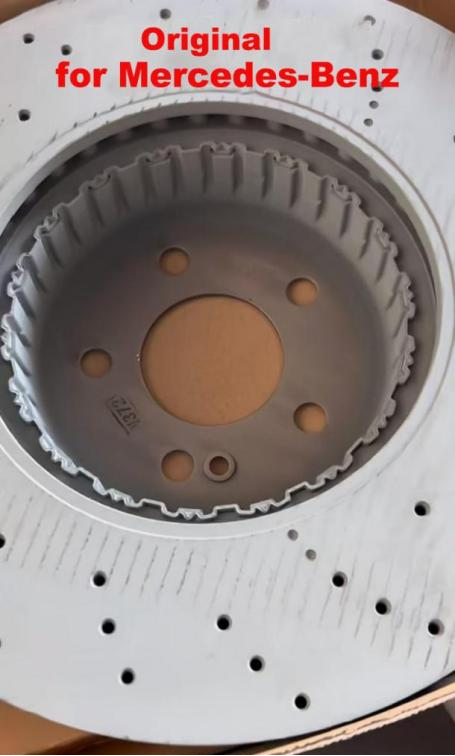

8. Drilling process:

To meet the original design requirements of certain models and the personalized customization needs of customers, we offer professional brake disc drilling services. Using high-precision CNC machining equipment, we strictly adhere to the original factory specifications or customer-defined parameters for precise drilling, ensuring that the hole layout is uniform and the hole diameter is accurate. The drilled discs, with their unique structural design, offer significant heat dissipation advantages: numerous well-distributed cooling holes effectively increase the air circulation area, accelerating heat dissipation during braking, reducing the peak temperature of the brake surface, and delaying material thermal degradation. Additionally, the drilling design facilitates the timely removal of brake dust and debris, reducing the interference of impurities on the friction surface, thereby enhancing braking stability and response sensitivity.

9. Paint spraying:

After completing the entire production and quality inspection process, we apply the Jiaomeite coating spray process to create a long-lasting protective barrier for the brake disc. Jiaomeite coating, a high-performance metal protection coating, is evenly applied through a special coating process, forming a dense and highly adhesive protective film on the surface of the brake disc. This coating not only provides excellent rust and oxidation resistance, effectively resisting the erosion of complex environments such as moisture, acids, and alkalis, significantly extending the brake disc's service life; it also exhibits outstanding high and low-temperature performance, maintaining the integrity of the coating and continuous protective function even under extreme conditions of sudden temperature changes during braking. Additionally, the Jiaomeite coating offers excellent wear resistance and impact resistance, further enhancing the overall performance of the brake disc, ensuring that the product remains in excellent condition even under harsh usage conditions.