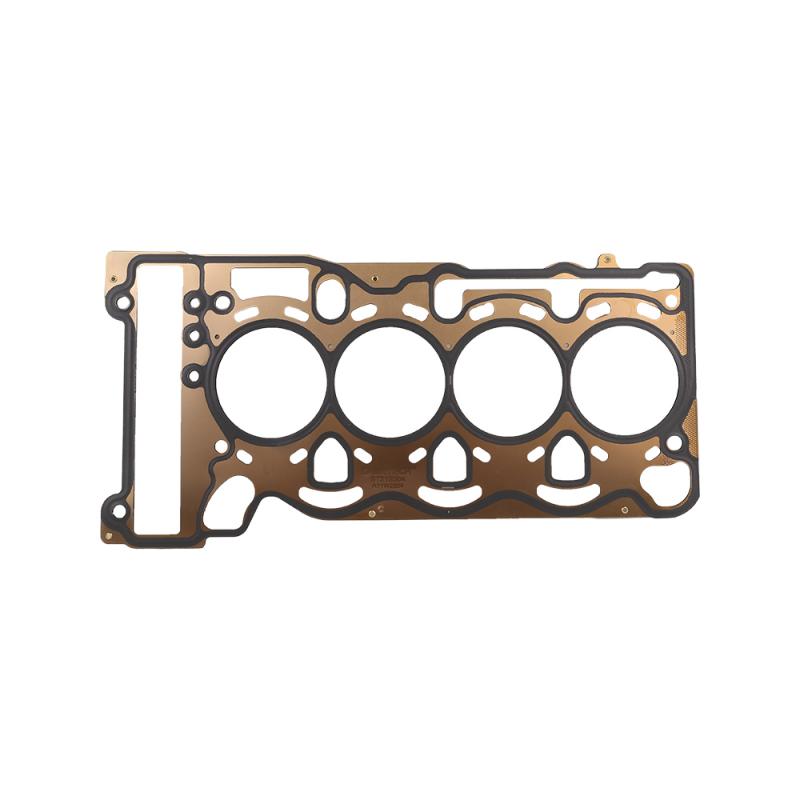

Engine cylinder head gasket introduction:

The engine cylinder head gasket is an object that seals the oil, cooling water and the gas inside the cylinder. Commonly used engine cylinder head gasket are asbestos (non-asbestos) acorn rubber composite gaskets, metal-coated (copper-clad iron-clad) gaskets, composite-coated gaskets, metal composite gaskets, metal rubber ring gaskets and other types. According to the different characteristics of raw materials, engine cylinder head gasket can be divided into: copper plate engine cylinder head gasket, composite plate engine cylinder head gasket and asbestos engine cylinder gasket. Apply fluorine rubber DAI-EL to the surface of the stainless steel sheet. DAI-EL has heat resistance that can withstand repeated heating and cooling, as well as excellent oil resistance and sealing.

Parameters of engine cylinder gasket:

| Parameter | Description |

| Material | Steel core + graphite/asbestos/metal glued to adapt to cylinder block deformation |

| Pressure resistance | High-pressure sealing to ensure the stability of the combustion chamber |

| Temperature range | Adapt to wide temperature range, suitable for high load conditions |

| Enhanced design | The metal ring strengthens the edge of the combustion hole and prevents the impact of the burning pad |

| Anti-leakage ability | Effectively prevent oil and coolant leakage and avoid pollution |

| Creep resistance | High elastic coating or stainless steel skeleton, long-term compression does not deform |

| Chemical resistance | Resist oil additives, coolant acidity and exhaust gas corrosion |

Performance advantages of engine cylinder gasket:

Our engine cylinder gasket has good sealing performance, which guarantees the efficient operation of the engine. Our engine cylinder gasket uses a steel core combined with graphite, asbestos or metal coating (Elring technology) to adapt to the deformation of the cylinder block and strongly seal the combustion chamber (withstand pressure>20MPa). The burn-proof pad design of our engine cylinder gasket strengthens the edge of the hole through a metal ring to resist high temperature shocks, especially suitable for diesel engines. Engine cylinder gasket has a temperature resistance range of -30℃~300℃, which adapts to turbocharging loads, prevents oil and coolant leakage, and avoids pollution. Based on innovative materials, our engine cylinder gasket guarantees the stability and reliability of the engine; The core advantage of this engine cylinder gasket is comprehensive protection and maintenance cost savings.

Product advantages of engine head gasket:

Our engine head gasket provides long life and reduces the risk of failure and repair. This engine head gasket uses creep-resistant materials such as fluorine rubber coating or stainless steel skeleton to ensure that it will not deform under long-term pressure. Engine head gasket has strong chemical resistance, resists oil additives, coolant acidity and EGR exhaust gas erosion, and extends its service life. In terms of design, engine head gasket is very durable and reliable, and operates efficiently in harsh working conditions. The characteristics of these engine head gasket are derived from advanced production technology, which greatly reduces the frequency of replacement. Overall, the advantages of engine head gasket include economy and sustainability, providing lasting support for the engine. The high cost performance of this engine head gasket allows users to enjoy worry-free driving.

How to install engine head gasket:

1. Clean and prepare the binding surface: Carefully clean the sealed binding surface of the cylinder head and cylinder block to remove rust, dirt or residues of old engine head gasket to ensure that the surface is clean.

2. Clean the bolt holes: Clean the bolt holes of the cylinder head and cylinder block, remove dirt and oil, check whether the thread is damaged, and ensure that the bolt rotates smoothly.

3. Check the binding surface: Use oilstone to remove the surface raised material, and use a knife-edge ruler to confirm the flatness of the binding surface (longitudinal ≤0.05mm, transverse ≤0.03mm) to adapt to the sealing requirements of the engine head gasket.

4. Fix the cylinder gasket for BMW: Fix the cylinder gasket for BMW to the cylinder block, check the surface of the gasket for damage, and ensure that it is intact.

5. Install the cylinder head: Install the cylinder head carefully to avoid scratching the sealing surface; pay attention to whether there are metal shavings and other residues falling to avoid contaminating the cylinder gasket for BMW.

6. Selection of bolts: Choose the cylinder head bolts recommended by the oems; When replacing the cylinder gasket for BMW, replace the new bolts and washers simultaneously, and lubricate the thread and the bottom surface of the head with lubricating oil.

7. Fastening bolts: Tighten the bolts in the order described by the OEMS; If you need to re-tighten, follow the re-tightening instructions to ensure that the cylinder gasket for BMW is firmly sealed.

About us:

We Sortech focus on the research and development and manufacturing of cylinder gasket for BMW, and are committed to providing customers with good sealing solutions. Our cylinder gasket for BMW uses high-quality materials, such as steel core combined with graphite, asbestos or metal coating, which makes it have good pressure resistance and sealing performance, adapt to cylinder block deformation, and effectively prevent oil and coolant leakage. The metal ring of cylinder gasket for BMW is reinforced to resist the impact of high-temperature gas, which is especially suitable for diesel engines under harsh operating conditions. Cylinder head gasket has strong creep resistance and chemical resistance, long-term use does not deform, and extends engine life. With its reliable performance and long life, our Sortech cylinder gasket for BMW significantly reduces maintenance costs and brings customers an efficient and stable experience. Choosing Sortechcylinder head gasket means choosing peace of mind and quality.

A: Our products have passed ISO/TS 16949 quality management system certification, and meet the European CE, Russian GOST and other regional standards. Specific certification can be provided according to customer needs.

A: Yes! Please provide your requirements or refer to our product catalogue on the website. We will send you detailed technical documents (including size, material, vehicle type, etc.).

A: The regular model is available in stock, and the delivery cycle is 3-5 working days; the production cycle of customized products needs to be confirmed according to the order.

A: Please provide the brand, model and year of the vehicle (such as BMW 2020), we will match the corresponding accessories.

A: We provide OEM number comparison service or verify compatibility through third-party tools.

A: The default quotation is the factory price (excluding tax). If you need FOB price, you need to specify the freight forwarder and bear the international freight, we will cooperate with you.

A: The larger the order volume, the higher the discount. For example: -MOQ 100 pieces: unit price $10. -MOQ 500 pieces: unit price $8. Specific step prices can be negotiated after the procurement plan is provided.

A: The quotation is not included in tax (tax number of customer is required for export tax exemption in China). If DDP (tax paid delivery) is required, additional tax confirmation is required.

A: You can send the purchase list by email or submit the order online (official website link), we will confirm within 24 hours.

A: The modification can be made free of charge before production; the cancellation during production will incur the material loss fee (30% of the order amount); the cancellation after delivery is not allowed.

A: The freight shall be borne by your company under FOB price; the cost to the destination port/denominated place shall be borne by us under CIF/DAP price.

A: To be provided: -Commercial invoice (including HS code). -Packing list. -Certificate of origin (FORM A). -Technical documents (e.g. product certification certificates). We can assist in preparing the documents, but the customer is responsible for customs clearance.

A: It can be agreed to take the spot selling price of the Bank of China at the time of signing the contract as the benchmark, or avoid the risk of volatility through forward exchange contracts.

A: 2 years and 60,000 kilometers, electronic components 1 year warranty.

A: Please provide photos, test report and batch number to confirm the quality problem: -Free replacement or repair within the warranty period (24 months); -Negotiate partial compensation for non-quality issues.

A: The return freight shall be borne (except for quality problems), and the return shall be confirmed by our quality inspection.

A: Provide multi-language installation video and graphic manual, complex accessories can arrange engineers for remote guidance.