Product introduction:

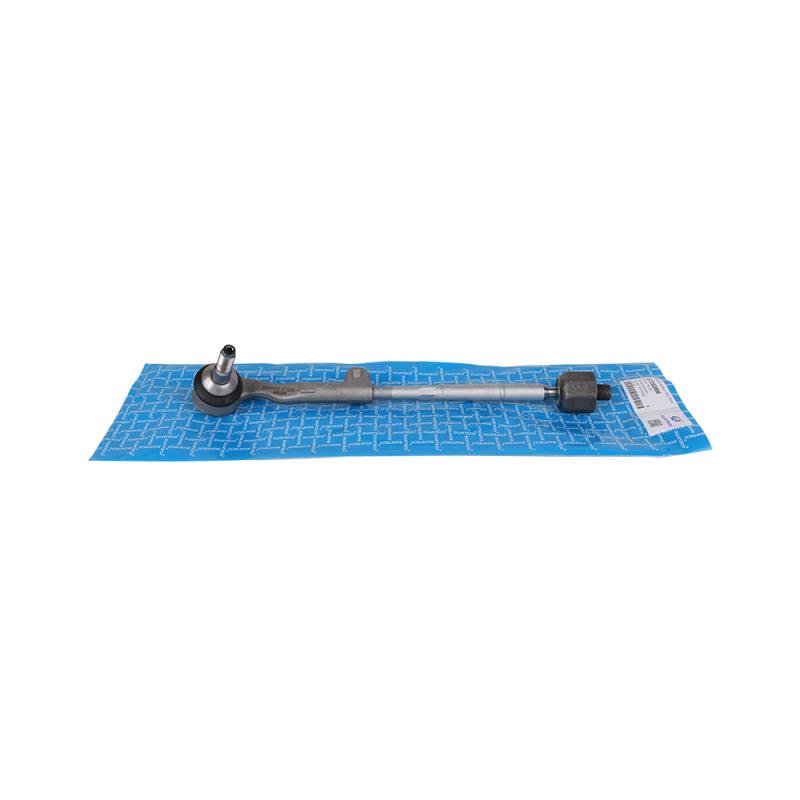

Tie rod assembly for BMW is mainly used in the suspension system of automobiles to connect and stabilize the wheels to ensure the stability and safety of the vehicle during driving. Our car tie rod assembly for BMW is usually composed of multiple components, including tie rods, joints, etc., which are suitable for different brands and models of cars.

Product parameters:

| Specific parameters | Performance indicators |

| Main material | High carbon chromium alloy steel/zinc alloy |

| Surface treatment | Galvanized/phosphated or stainless steel material |

| Tensile strength | ≥800MPa |

| Improved wear resistance | More than 50% |

| Lubrication system | Lithium-based/PTFE special grease |

| Temperature range | -30℃~120℃ |

| Ball head craft | Precision polishing process |

| Reduced steering resistance | 0.2 |

| Dynamic load capacity | ≥2000kg |

| Applicable models | Heavy-duty scenarios such as SUVs/commercial vehicles |

| Shock absorption design | Optimize the internal buffer structure |

| Anti-shedding structure | Locking circlip/riveting process |

| Sealing system | Multi-layer rubber/PTFE dust cover |

| Increased life of dust cover | More than 30% |

| Fatigue test standard | SAE J492 |

Material advantage:

Our company's car tie rod assembly for BMW adopts high-carbon chromium alloy steel and advanced quenching technology to ensure that the tensile strength is ≥800MPa and the wear resistance is increased by more than 50%. This design makes car tie rod assembly kit durable in salt spray and humid environments, and can significantly extend its service life.

Process advantage:

We reduce steering resistance by 20% through precision polishing technology, and our company's car tie rod assembly kit provides sensitive steering wheel response and a stable driving experience. Combined with the carrying capacity of dynamic load ≥2000kg, our car tie rod assembly kit is perfectly adapted to heavy-duty scenarios such as SUVs and commercial vehicles.

Safety protection advantages:

Our tie rod assembly kit has a built-in locking circlip and a multi-layer PTFE dust cover, which can effectively prevent the ball head from falling off and sediment intrusion, and improve the life of the dust cover by more than 30%.Through the 100,000 fatigue tests of the SAE J492 standard, tie rod assembly kit has no loosening and deformation under different working conditions, ensuring driving safety and reflecting the company's emphasis on user safety.

Performance advantage:

Our tie rod assembly kit is equipped with lithium-based/PTFE special grease, with a temperature resistance range of -30℃~120℃ to avoid abnormal dry grinding; At the same time, our tie rod assembly kit strengthens the internal buffer structure to reduce the transmission of road bumps. These characteristics make auto tie rod assembly perform well in driving comfort.

Certification advantage:

Our auto tie rod assembly adapts to a variety of environments through waterproof and dustproof design, anti-rust and anti-corrosion treatment; This auto tie rod assembly combines high load capacity, auto tie rod assembly is widely used in commercial and passenger cars, and our products have been recognized by the industry to provide reliable solutions for customers around the world.

About us:

We focus on the research and development and manufacturing of auto parts, using high-carbon chromium alloy steel and advanced quenching technology to ensure the performance and long-term durability of auto tie rod assembly. Through precision polishing, multi-layer dustproof and special lubrication technology, our auto tie rod assembly improves handling stability and driving comfort. All our tie rod assemblies have undergone rigorous fatigue testing and meet international standards to provide users with a safe and reliable driving experience.

A: Our products have passed ISO/TS 16949 quality management system certification, and meet the European CE, Russian GOST and other regional standards. Specific certification can be provided according to customer needs.

A: Yes! Please provide your requirements or refer to our product catalogue on the website. We will send you detailed technical documents (including size, material, vehicle type, etc.).

A: The regular model is available in stock, and the delivery cycle is 3-5 working days; the production cycle of customized products needs to be confirmed according to the order.

A: Please provide the brand, model and year of the vehicle (such as BMW 2020), we will match the corresponding accessories.

A: We provide OEM number comparison service or verify compatibility through third-party tools.

A: The default quotation is the factory price (excluding tax). If you need FOB price, you need to specify the freight forwarder and bear the international freight, we will cooperate with you.

A: The larger the order volume, the higher the discount. For example: -MOQ 100 pieces: unit price $10. -MOQ 500 pieces: unit price $8. Specific step prices can be negotiated after the procurement plan is provided.

A: The quotation is not included in tax (tax number of customer is required for export tax exemption in China). If DDP (tax paid delivery) is required, additional tax confirmation is required.

A: You can send the purchase list by email or submit the order online (official website link), we will confirm within 24 hours.

A: The modification can be made free of charge before production; the cancellation during production will incur the material loss fee (30% of the order amount); the cancellation after delivery is not allowed.

A: The freight shall be borne by your company under FOB price; the cost to the destination port/denominated place shall be borne by us under CIF/DAP price.

A: To be provided: -Commercial invoice (including HS code). -Packing list. -Certificate of origin (FORM A). -Technical documents (e.g. product certification certificates). We can assist in preparing the documents, but the customer is responsible for customs clearance.

A: It can be agreed to take the spot selling price of the Bank of China at the time of signing the contract as the benchmark, or avoid the risk of volatility through forward exchange contracts.

A: 2 years and 60,000 kilometers, electronic components 1 year warranty.

A: Please provide photos, test report and batch number to confirm the quality problem: -Free replacement or repair within the warranty period (24 months); -Negotiate partial compensation for non-quality issues.

A: The return freight shall be borne (except for quality problems), and the return shall be confirmed by our quality inspection.

A: Provide multi-language installation video and graphic manual, complex accessories can arrange engineers for remote guidance.